Smart hearing health

Challenge

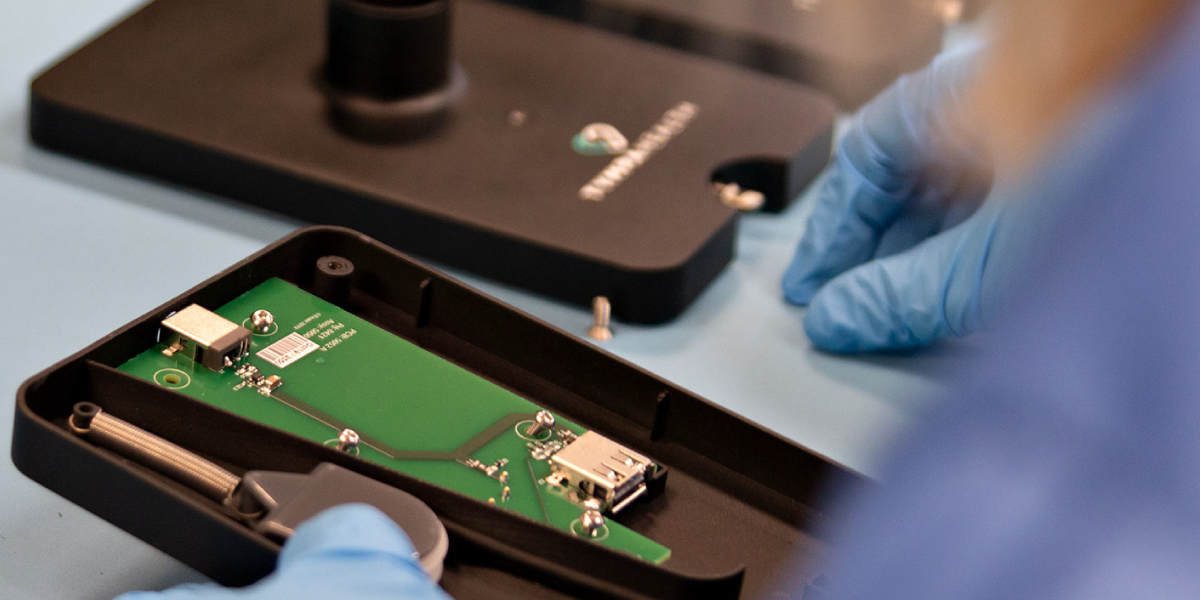

The commercialisation of a start-up company’s smartphone-enabled otoscope.

Approach

We advanced the client’s initial product vision through two stages of development by applying user feedback gained during use of a first generation ‘pilot’ system. We identified and introduced new features whilst optimising usability and handling for a second generation ‘commercial’ system. These iterations involved our designers and engineers working seamlessly with a Singapore-based manufacturing partner selected by Team Consulting for TympaHealth.

Outcome

The TympaHealth device is a portable smartphone-enabled otoscope with accompanying smartphone app; the world’s first all-in-one hearing health assessment system. It allows trained staff to carry out a full ear examination, a hearing test and to safely perform ear wax removal with microsuction, improving the patient pathway. Within 15 months we achieved the industrialisation and CE marking of this Class I medical device, compliant with the MDR.