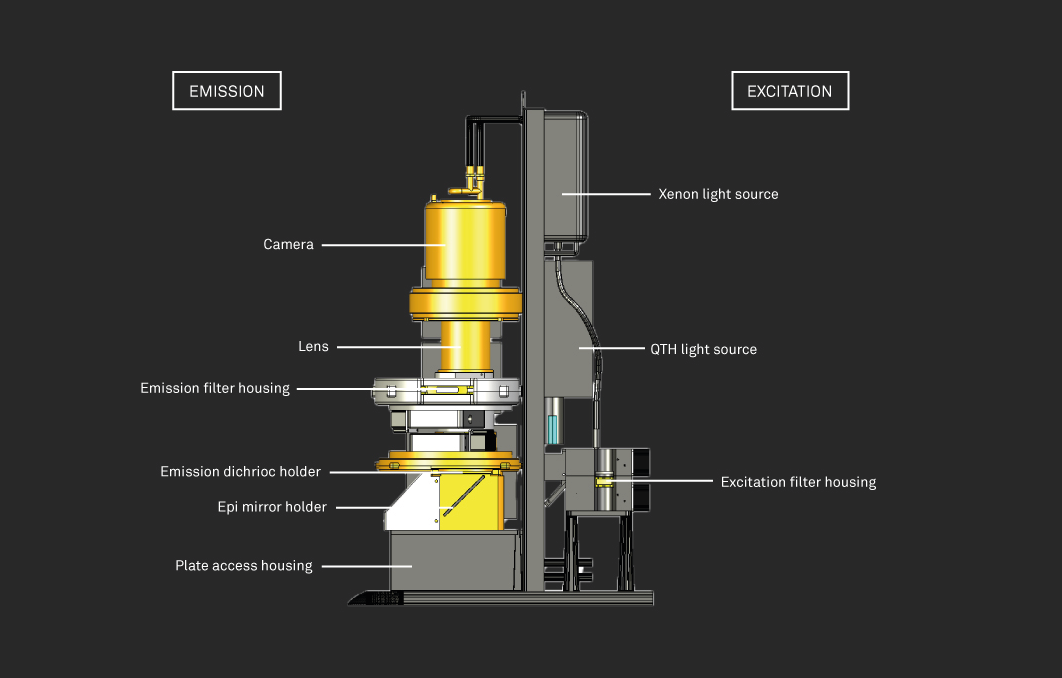

Fluorescence and luminescence analyzer

Challenge

Design and engineer a fluorescence and luminescence microplate reader for high throughput analysis.

Approach

We deployed a cross-functional team to solve various optical, exterior design and prototyping challenges.

Outcome

The first set of prototypes were built and tested in our facilities and the LEADseeker™ system was successfully launched as a fully automated plate reader capable of scanning and processing over 1000 microplates per day.